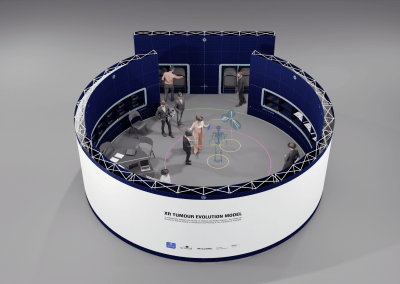

Distributed and cloud-based control at field-level for systems interacting with soft bodies

David Tomzik, Doctoral Candidate, Department of Mechanical Engineering

Addressing the need for increased flexibility in automation and research

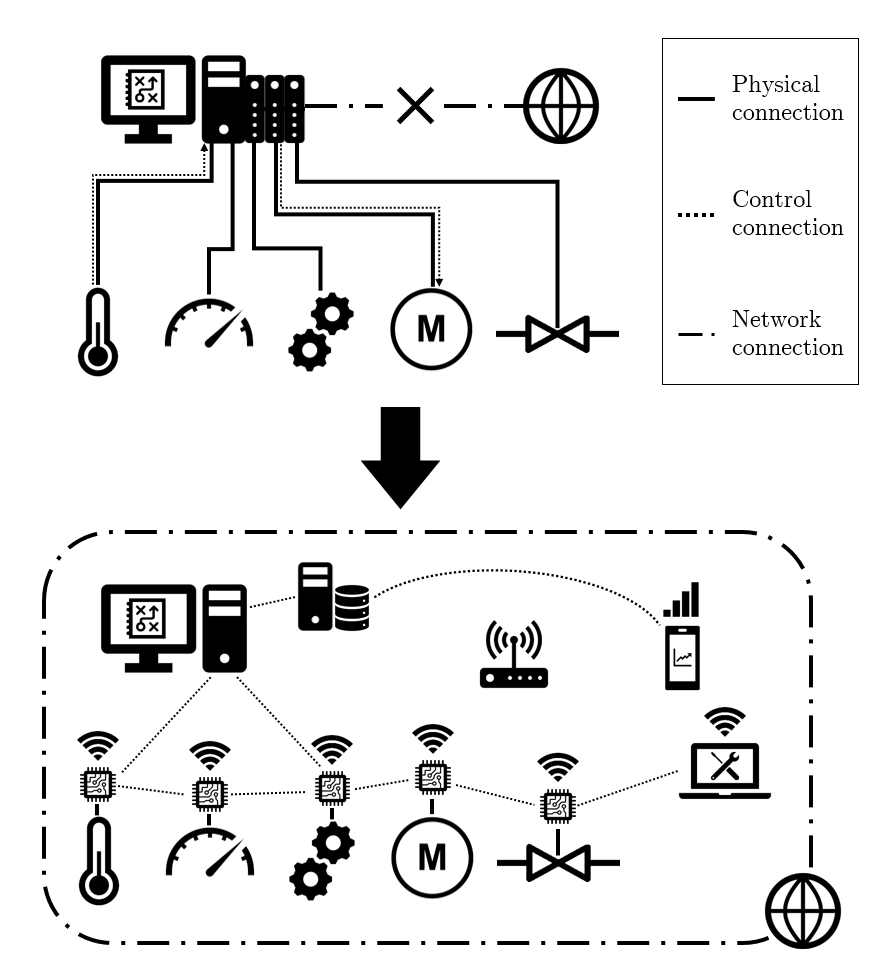

Systems that interact with soft bodies can face significant challenges. In the areas of agriculture (e.g. fruit harvesting, meat processing) and medical engineering, ill-defined, varying properties of objects and environment pose an obstacle for possible automation. A way to deal with the increased uncertainty is to use innovative sensors and actors. These sensors and actors produce varied and extensive amounts of data. A possible control system needs to provide increased computational resources and uncomplicated integration. Conventional control systems (often located next to the machine) lack these traits. We propose a new approach: individual components equipped with elementary computational resources, directly connected to an Ethernet-based network and are able to communicate with each other. Through the network, computationally expensive tasks can be off-loaded to components in the cloud. The components, both hardware and software, of such system and control can be easily combined and re-arranged.

Starting at the field level

To connect and communicate within a network, a component needs an interface and elementary computational resources. If it is not inherent, it needs to be added. Gateway devices that connect multiple sensors or components to Ethernet networks, so called IoT hubs, are already available. However, we wish to develop a similar solution by taking advantage of highly integrated and affordable Systems-on-a-Chip (SoC). Their price and size are small enough to bring connectivity directly to the individual component. The computational capability will also enable elementary control functionalities. Simple control loops can be realised by sensor and actor components communicating directly, eliminating the additional control instance in between.

Platform for a control network

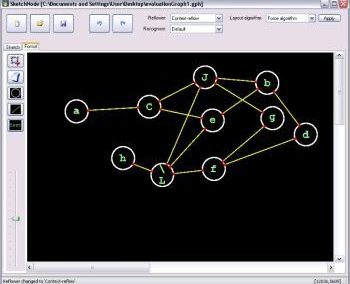

Each hard- and software component can be seen as a node with clearly defined functionalities, outputs and inputs that are part of a control network. To allow easy and seamless communication, the nodes need to be implemented with a common interface. A good candidate is the industrial OPC UA standard. It is versatile enough to accommodate different platforms and use cases. Additionally, the nodes will require internal flexibility to allow for changes of parameters and the control system arrangement. Crucial parts of this project will be the design of a node template and the implementation of methods to introduce nodes to each other and to set up the control connections. The platform will cover aspects of hardware, software and firmware alike.

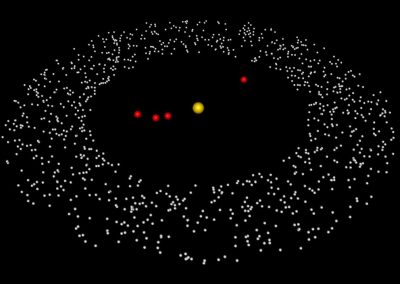

Figure 1. Transformation from central to a distributed control system based on an Ethernet network.

Initial case study: retrofitting an 11-Year old robot into the Cloud

To assess the capabilities of possible hardware and to acquaint myself with network technology, I fitted an 11-year old industrial robot with a WiFi-enabled SoC, the ESP8266 from Espressif. The robot control system consists of a Programmable Logic Control (PLC) and a computer running Windows Embedded. For this operating system, I wrote a small program that takes the position information, available in the in the control system, and sends it to the ESP8266, which is connected via Serial Port. Even though the Serial Port has only limited bandwidth, it is easy to use, sufficient for this application and does not interfere with the existing setup of the robot within the laboratory.

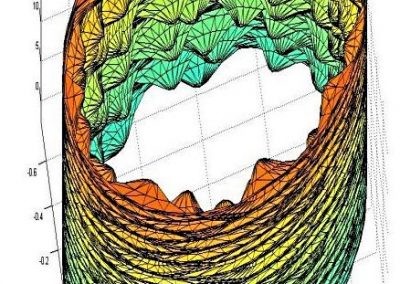

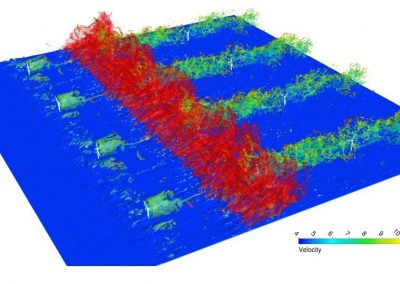

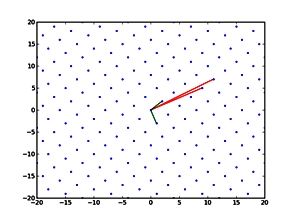

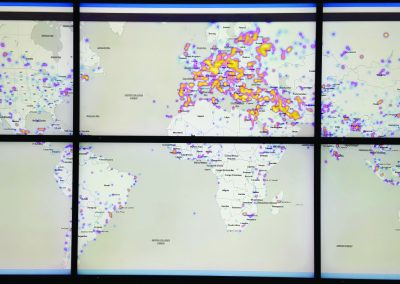

The ESP8266 supports WiFi and is connected to the University network. It forwards the machine data, received at the Serial Port, to a MQTT message server running on a vrtual machine. This message server can further distribute the data to various other components within the network. I chose to build a simple dashboard that visualizes the robot in 3D in real-time. The IIS webserver receives the machine data and hands it further down to the webclients. The website incorporates the three.js library that helps to visualize 3D content using HTML5. Possible additional features are the storage of the obtained machine data for further analysis and optimisation.

The use of a research virtual machine

The Centre for eResearch equipped me with a virtual machine that I use as a message and web server. They helped me to migrate my project from the Azure Cloud Platform into the University network and provided valuable advice on how to realise my plans. Additionally, I was invited as a beta tester for the Nectar platform. It enables researchers in Australia and New Zealand to easily deploy and connect virtual machines accessible from the internet – similar to solutions from commercial vendors like Microsoft or Google. I expect this service to be a very valuable tool during my research.

See more case study projects

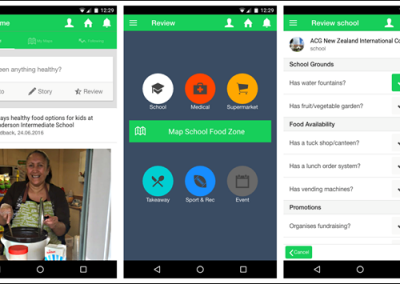

Our Voices: using innovative techniques to collect, analyse and amplify the lived experiences of young people in Aotearoa

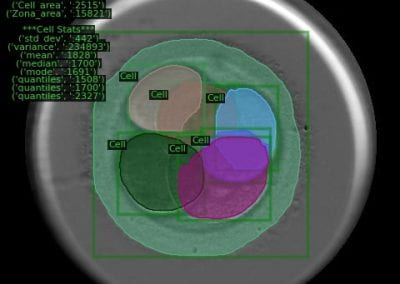

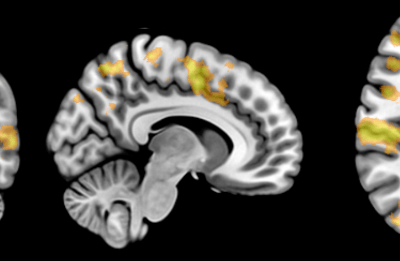

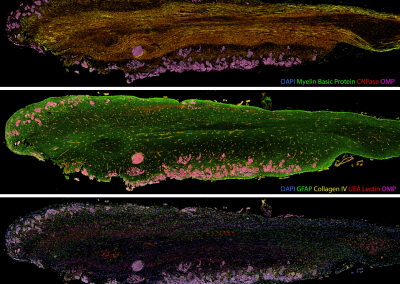

Painting the brain: multiplexed tissue labelling of human brain tissue to facilitate discoveries in neuroanatomy

Detecting anomalous matches in professional sports: a novel approach using advanced anomaly detection techniques

Benefits of linking routine medical records to the GUiNZ longitudinal birth cohort: Childhood injury predictors

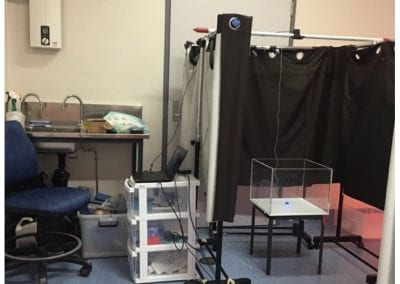

Using a virtual machine-based machine learning algorithm to obtain comprehensive behavioural information in an in vivo Alzheimer’s disease model

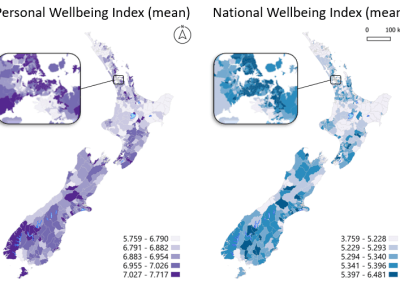

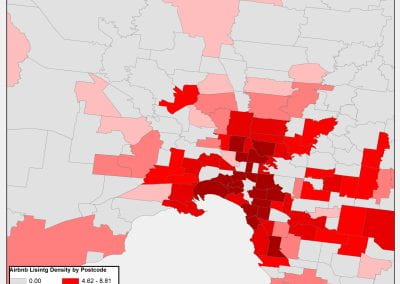

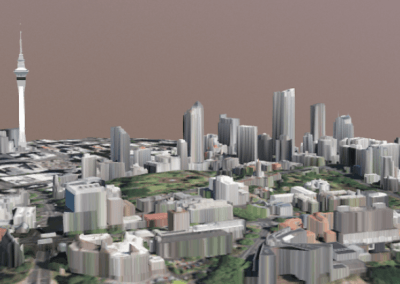

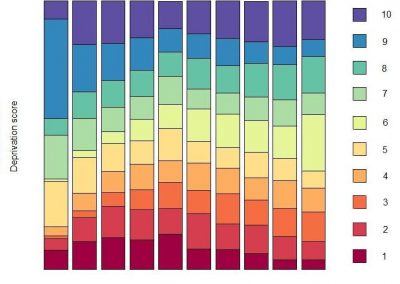

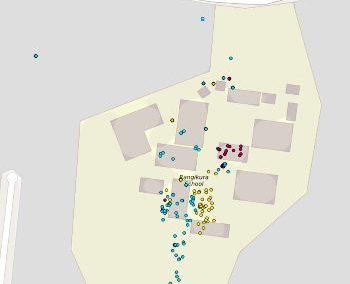

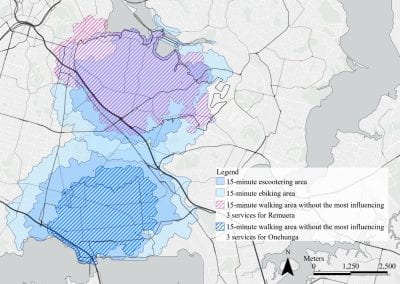

Mapping livability: the “15-minute city” concept for car-dependent districts in Auckland, New Zealand

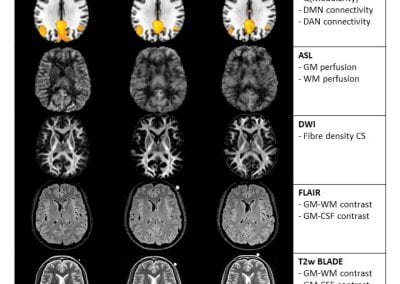

Travelling Heads – Measuring Reproducibility and Repeatability of Magnetic Resonance Imaging in Dementia

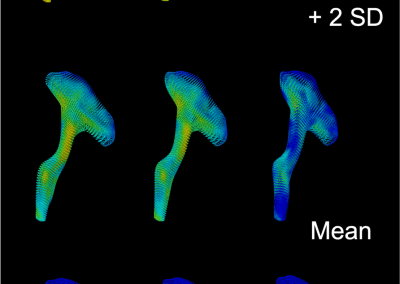

Novel Subject-Specific Method of Visualising Group Differences from Multiple DTI Metrics without Averaging

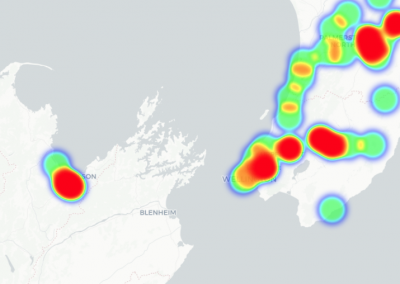

Re-assess urban spaces under COVID-19 impact: sensing Auckland social ‘hotspots’ with mobile location data

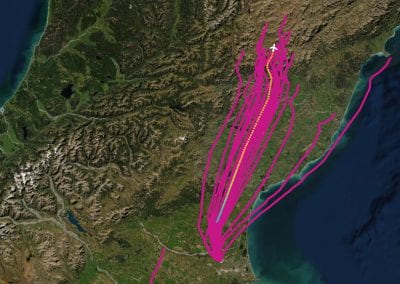

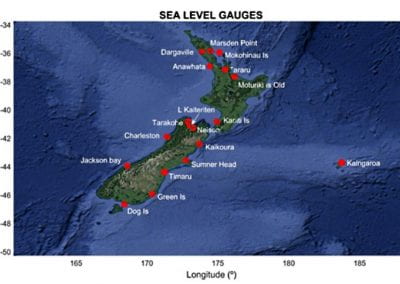

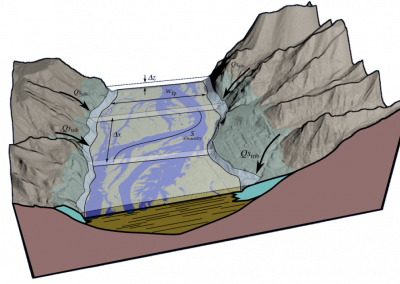

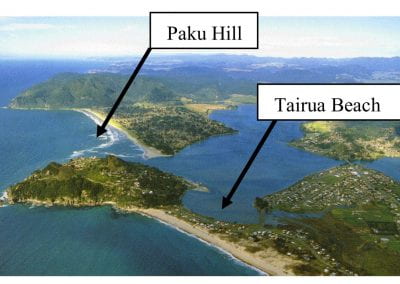

Aotearoa New Zealand’s changing coastline – Resilience to Nature’s Challenges (National Science Challenge)

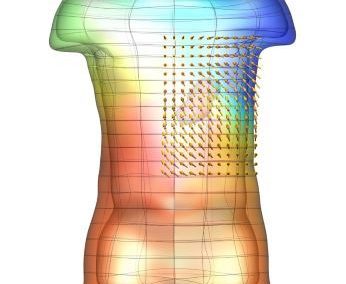

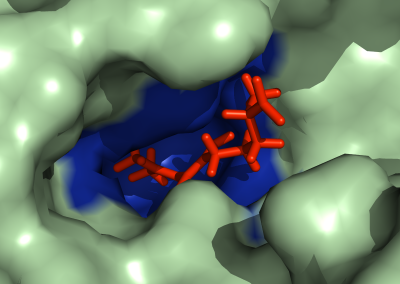

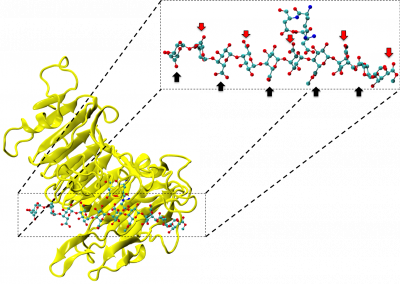

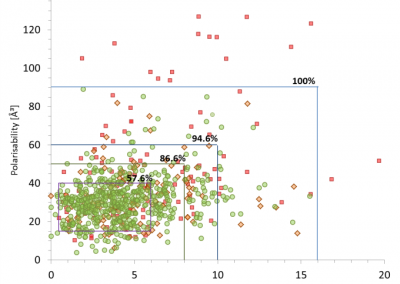

Proteins under a computational microscope: designing in-silico strategies to understand and develop molecular functionalities in Life Sciences and Engineering

Coastal image classification and nalysis based on convolutional neural betworks and pattern recognition

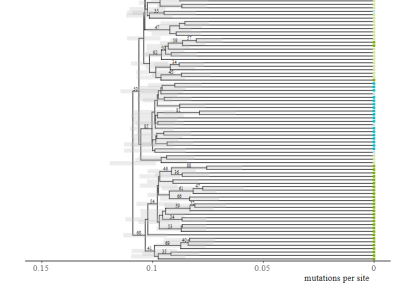

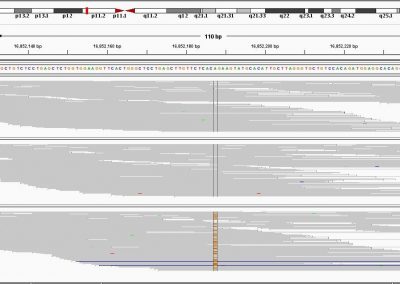

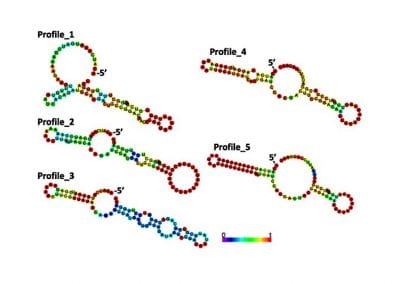

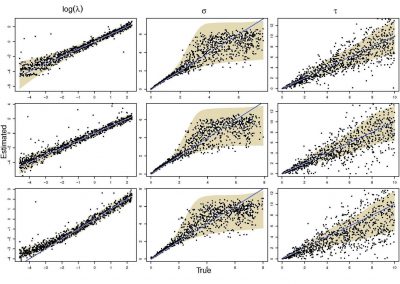

Determinants of translation efficiency in the evolutionarily-divergent protist Trichomonas vaginalis

Measuring impact of entrepreneurship activities on students’ mindset, capabilities and entrepreneurial intentions

Using Zebra Finch data and deep learning classification to identify individual bird calls from audio recordings

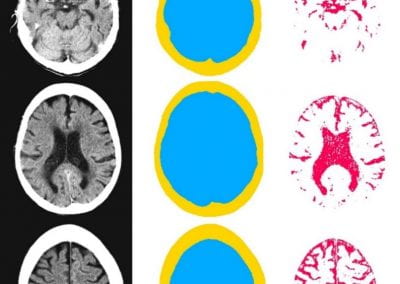

Automated measurement of intracranial cerebrospinal fluid volume and outcome after endovascular thrombectomy for ischemic stroke

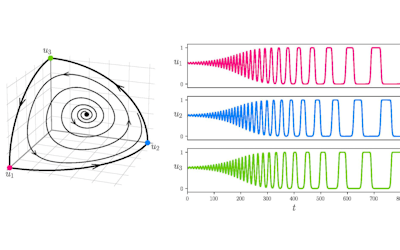

Using simple models to explore complex dynamics: A case study of macomona liliana (wedge-shell) and nutrient variations

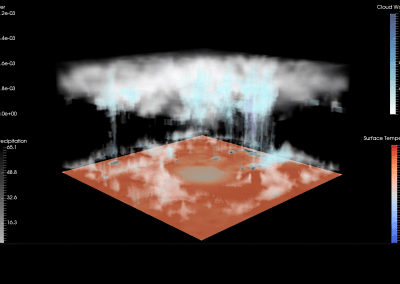

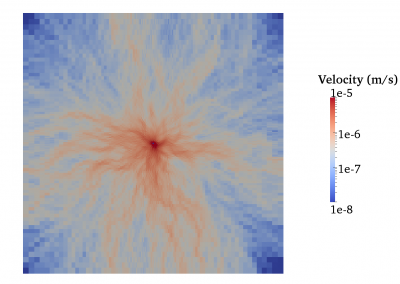

Fully coupled thermo-hydro-mechanical modelling of permeability enhancement by the finite element method

Modelling dual reflux pressure swing adsorption (DR-PSA) units for gas separation in natural gas processing

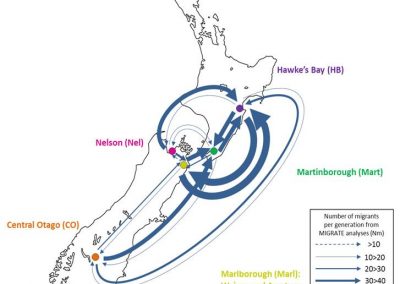

Molecular phylogenetics uses genetic data to reconstruct the evolutionary history of individuals, populations or species

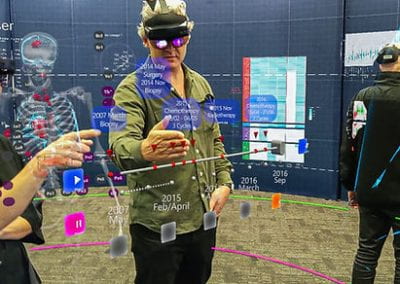

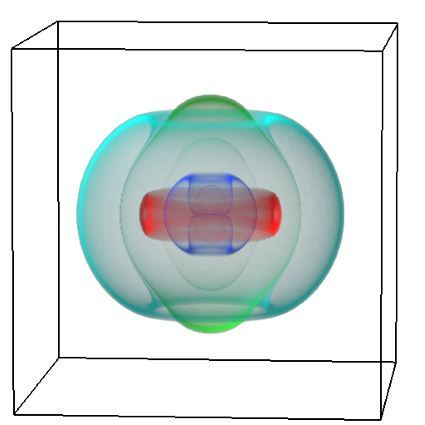

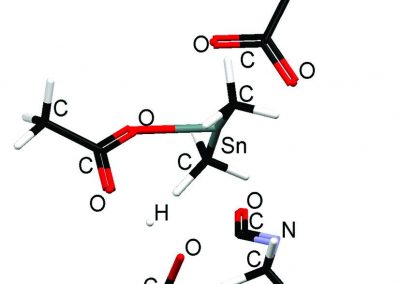

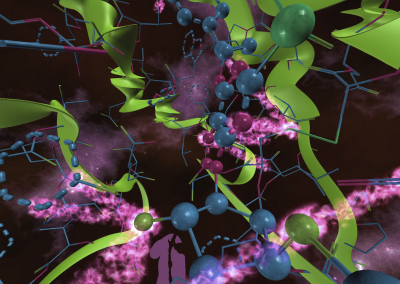

Wandering around the molecular landscape: embracing virtual reality as a research showcasing outreach and teaching tool