Engine knock in a spark-ignition engine with hydrogen supplementation

Yu Chen, Department of Mechanical Engineering

Engine knock

Spark-ignition (SI) engines play an important role in our lives, particularly in the transportation sector. Although these engines have been studied widely over the past decades, there are still some crucial challenges that we have to face. The most important challenges are:

- Reserves of fossil fuels are decreasing year by year thus, substitutes for gasoline need to be found.

- Emissions, such as CO2, are of concern. They have become a significant environmental issue in recent years, and need to be reduced.

- Knock – an abnormal combustion that is caused by autoignition of the unburnt air-fuel mixture. The efficiency of an SI engine is limited by this phenomenon.

Spark-ignition (SI) engines play an important role in our lives, particularly in the transportation sector. Although these engines have been studied widely over the past decades, there are still some crucial challenges that we have to face. The most important challenges are:

- Reserves of fossil fuels are decreasing year by year thus, substitutes for gasoline need to be found.

- Emissions, such as CO2, are of concern. They have become a significant environmental issue in recent years, and need to be reduced.

- Knock – an abnormal combustion that is caused by autoignition of the unburnt air-fuel mixture. The efficiency of an SI engine is limited by this phenomenon.

H2 is renewable and carbon free, and has been considered as an alternative fuel for SI engines. The unique properties of H2; give it a higher knock resistance, and technically, the efficiency of H2 fuelled SI engines should be improved. However, the low energy density of H2 suggests that it is more feasible to use it as a supplement, rather than as the sole fuel in an SI engine.

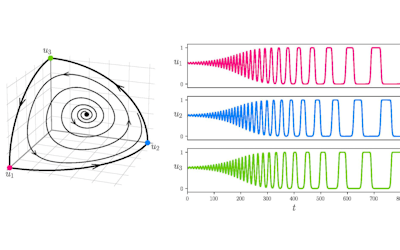

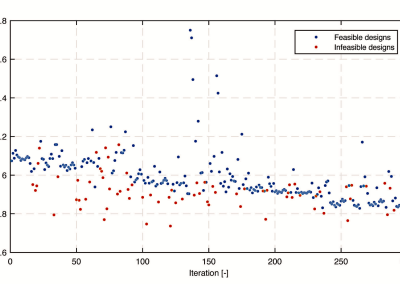

My research is focussed on the knock behaviour of the SI engine with H2 supplementation. The quantification of knock can be categorised into two aspects: knock tendency and knock intensity. Knock tendency is normally related to the possibility of occurrence of knock under given conditions. Knock intensity is normally considered to deal with the pressure oscillation and its energy content during knocking. While these two aspects can be studied experimentally, the chemical kinetics of gasoline, air, and H2 reactions under engine operating conditions can be investigated by computer simulation.

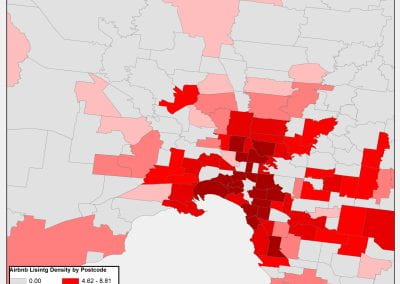

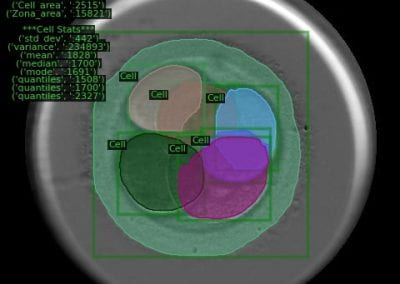

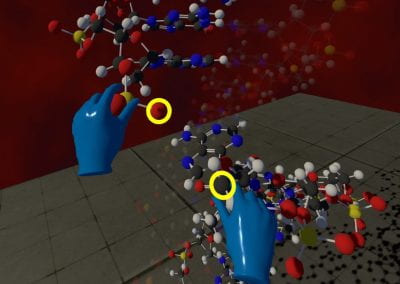

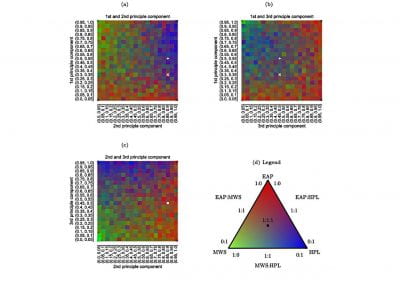

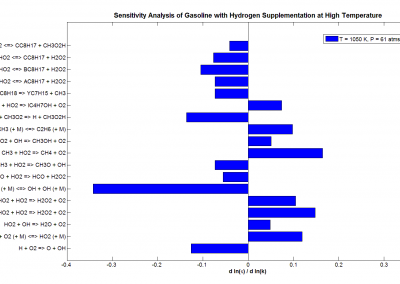

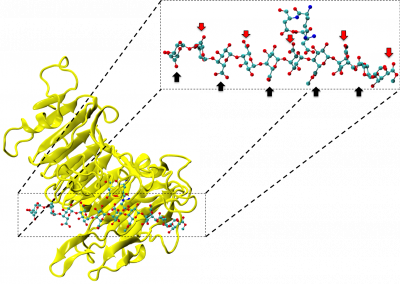

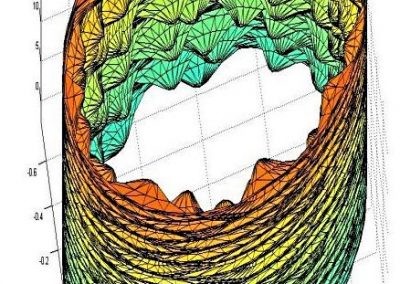

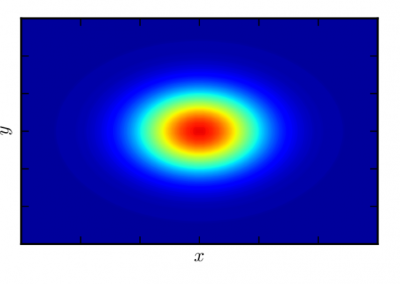

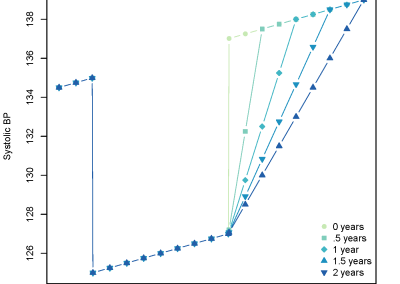

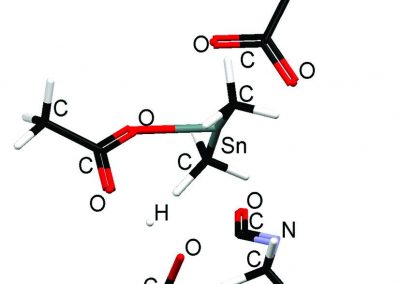

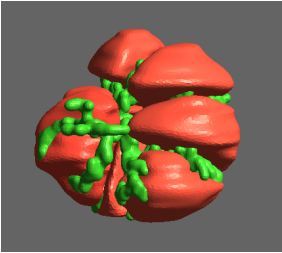

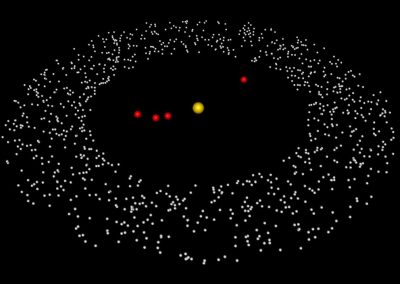

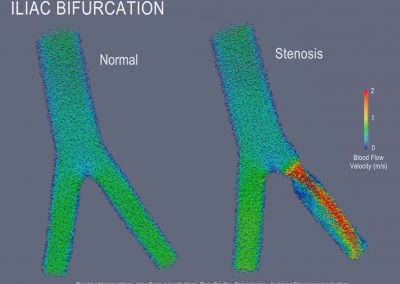

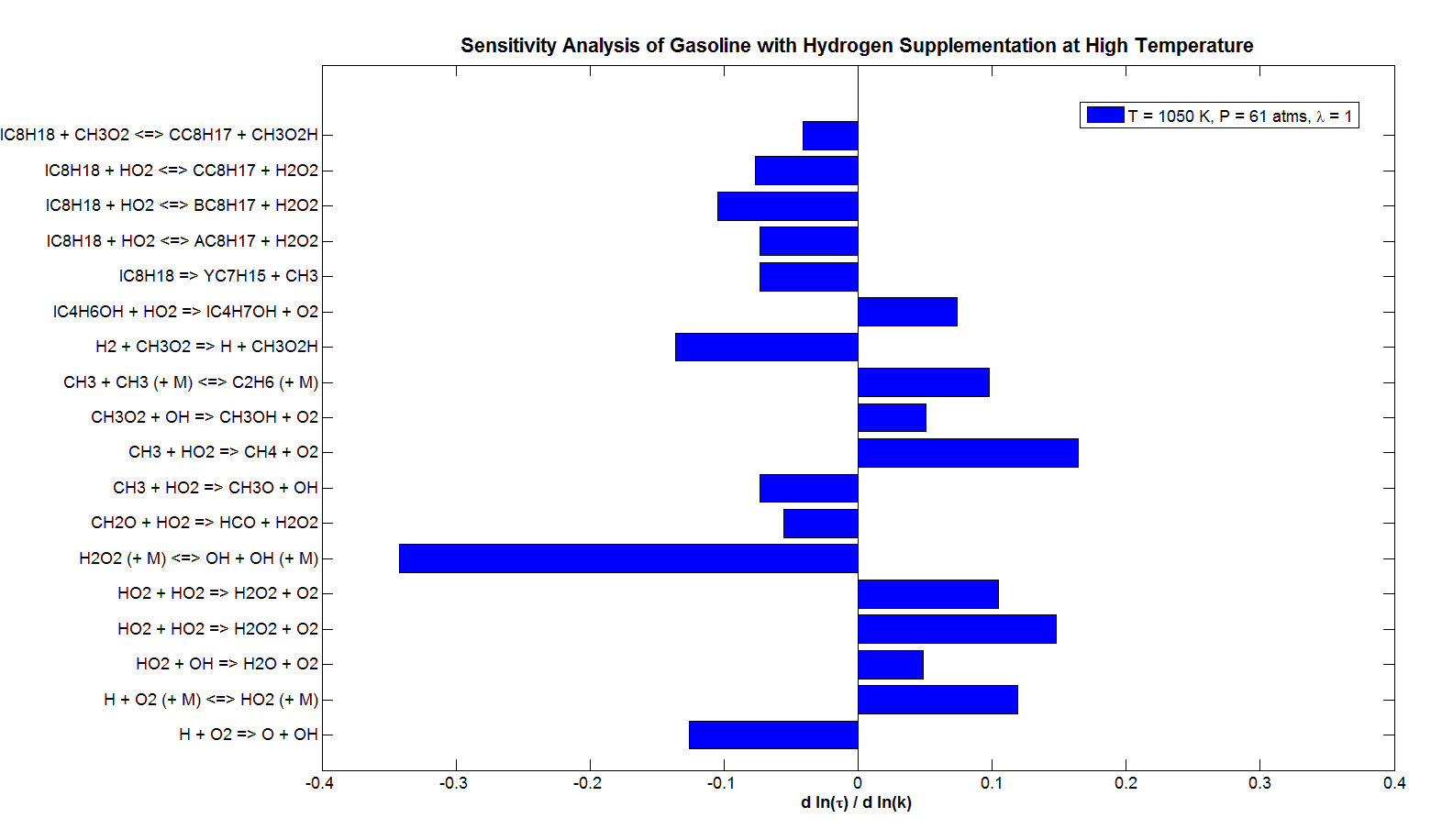

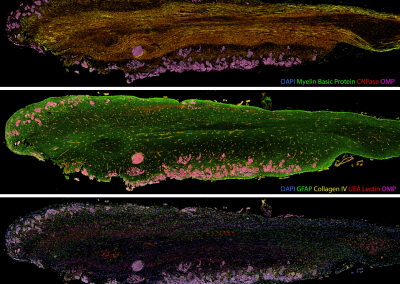

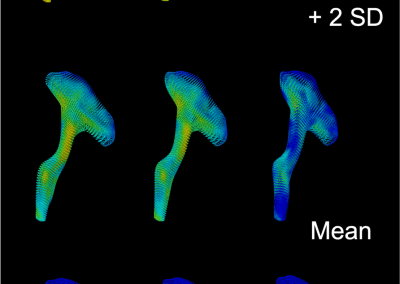

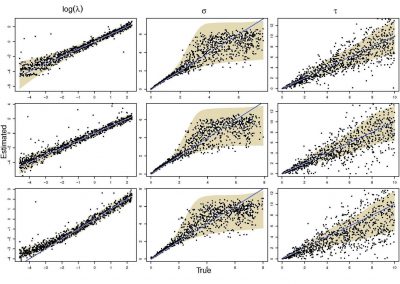

Figure1: Simulated sensitivity coefficients of the ignition delay time (𝒯) with respect to the rate constants (k) at the stoichiometric condition. Sensitivity coefficients are shown (as percentages) on the x-axis, and elementary reactions are shown on the y-axis. Only sensitivities greater than 3% are shown. Fuel: gasoline (91 octane rating) with 12.5% of the available energy being due to the H2 supplement. Engine operating conditions are temperature = 1050 K, pressure = 61 atm.

Multi-processing on the Pan cluster

The comprehensive model used in this study was developed by a group at Lawrence Livermore National Laboratory. This chemical kinetic model includes n-heptane, iso-octane, and hydrogen mechanisms, with approximately 1500 species and 6000 elementary

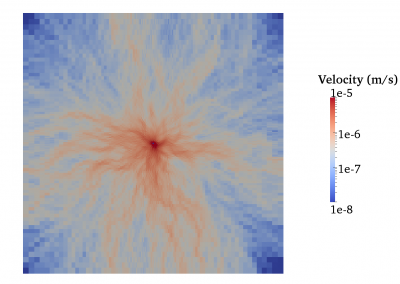

reactions. The open-source package Cantera is used to solve the kinetic model. One of my goals is to investigate how H<sub>2</sub> affects the knock behaviour of gasoline under engine operating conditions. This is done by analysing the relative sensitivities of ignition delay time (a key factor that influences engine knock) with respect to the chemical rate constants. An example is shown in Figure 1.

Note that a sensitivity of x percent with respect to a particular rate constant indicates that, in response to a 100 percent change of the rate constant, the ignition delay time is estimated to change by x percent. As there are approximately 6000 elementary reactions in the mechanism, the forward and backward reactions of many of these elementary reactions are separated. This means that approximately 9000 simulations have to be done for one sensitivity analysis at a particular engine operating condition (temperature and pressure).

Based on a computer with Intel Core i5 3.33 GHz processor, the time consumption for an individual simulation of the sensitivity analysis ranges from a few hours to a few days, depending on the engine operating conditions. This means that completing one sensitivity analysis on one personal computer would require a few years, which is infeasible. However, by utilising the Pan cluster facility at the University of Auckland, hundreds of simulations can be performed at the same time. Now, the time consumption of a sensitivity analysis only requires from a few days to a fortnight, which makes the work feasible.

The next task will be to compute temperature profiles of the unburnt air-fuel mixture in the compression and combustion processes. This will be based on in-cylinder pressure data from my experiments. From there, I will apply the chemical kinetic model under the temperature profile, to determine the mole fraction of species that play a significant role in engine knock, thereby finding kinetically how H2 supplementation affects the knock behaviour of an SI engine.

See more case study projects

Our Voices: using innovative techniques to collect, analyse and amplify the lived experiences of young people in Aotearoa

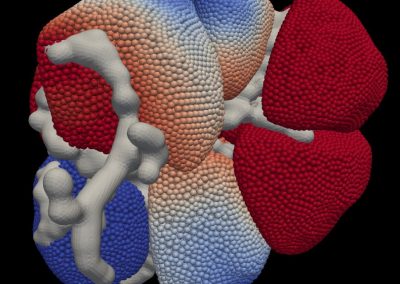

Painting the brain: multiplexed tissue labelling of human brain tissue to facilitate discoveries in neuroanatomy

Detecting anomalous matches in professional sports: a novel approach using advanced anomaly detection techniques

Benefits of linking routine medical records to the GUiNZ longitudinal birth cohort: Childhood injury predictors

Using a virtual machine-based machine learning algorithm to obtain comprehensive behavioural information in an in vivo Alzheimer’s disease model

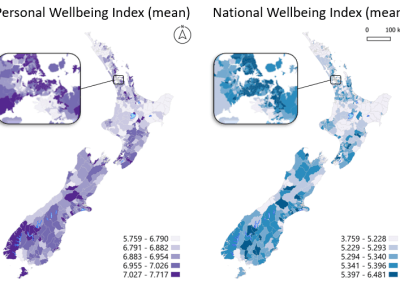

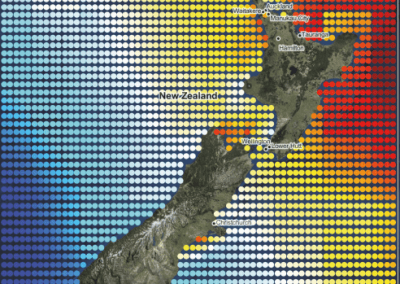

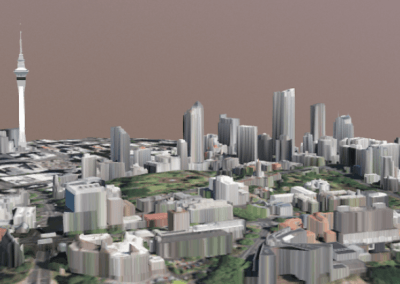

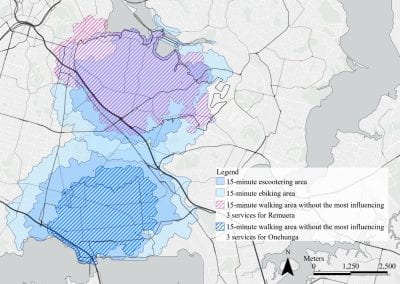

Mapping livability: the “15-minute city” concept for car-dependent districts in Auckland, New Zealand

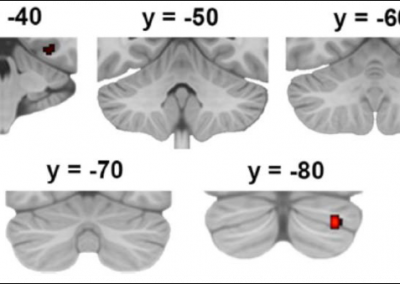

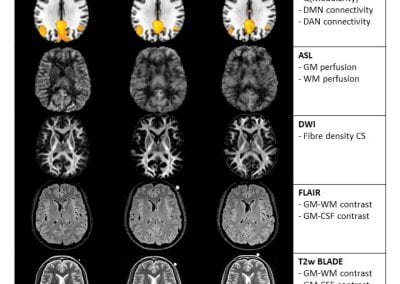

Travelling Heads – Measuring Reproducibility and Repeatability of Magnetic Resonance Imaging in Dementia

Novel Subject-Specific Method of Visualising Group Differences from Multiple DTI Metrics without Averaging

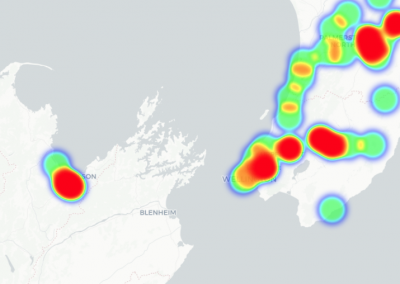

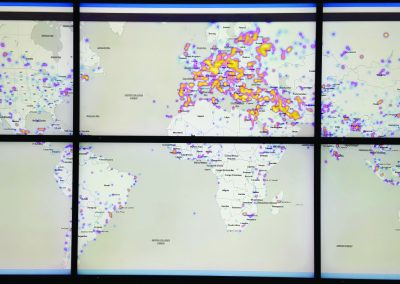

Re-assess urban spaces under COVID-19 impact: sensing Auckland social ‘hotspots’ with mobile location data

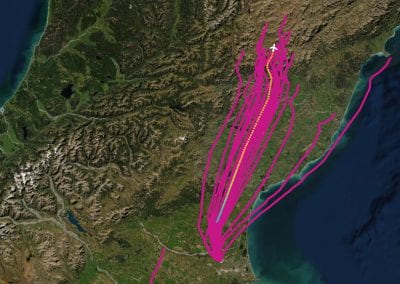

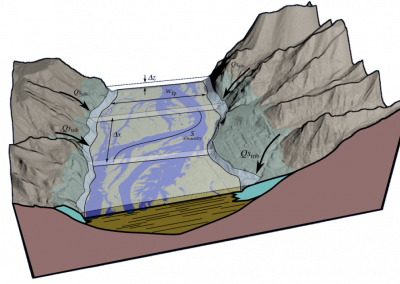

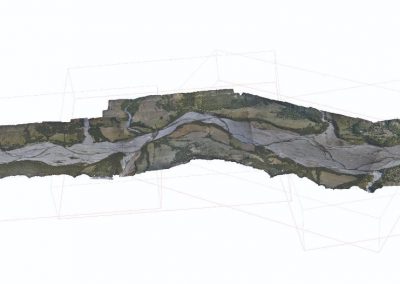

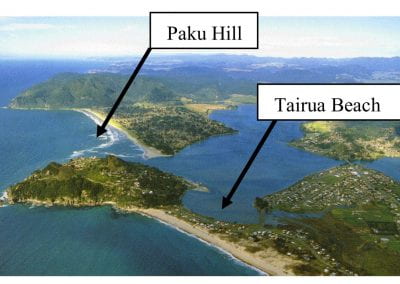

Aotearoa New Zealand’s changing coastline – Resilience to Nature’s Challenges (National Science Challenge)

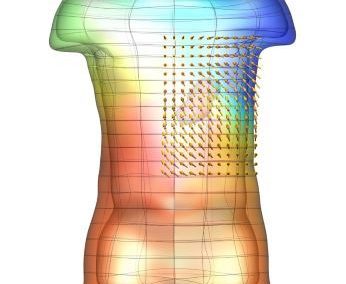

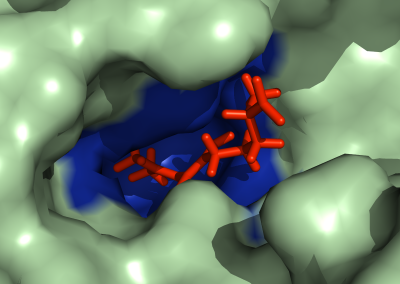

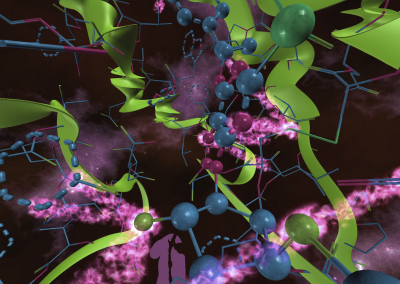

Proteins under a computational microscope: designing in-silico strategies to understand and develop molecular functionalities in Life Sciences and Engineering

Coastal image classification and nalysis based on convolutional neural betworks and pattern recognition

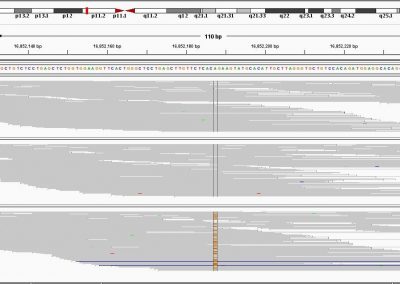

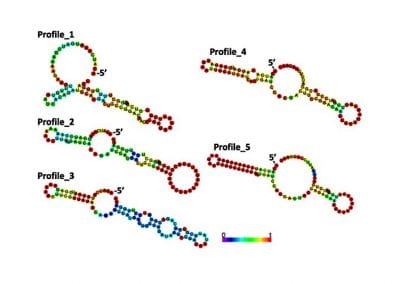

Determinants of translation efficiency in the evolutionarily-divergent protist Trichomonas vaginalis

Measuring impact of entrepreneurship activities on students’ mindset, capabilities and entrepreneurial intentions

Using Zebra Finch data and deep learning classification to identify individual bird calls from audio recordings

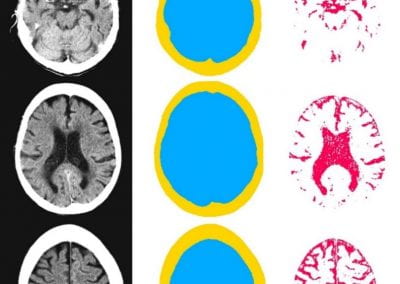

Automated measurement of intracranial cerebrospinal fluid volume and outcome after endovascular thrombectomy for ischemic stroke

Using simple models to explore complex dynamics: A case study of macomona liliana (wedge-shell) and nutrient variations

Fully coupled thermo-hydro-mechanical modelling of permeability enhancement by the finite element method

Modelling dual reflux pressure swing adsorption (DR-PSA) units for gas separation in natural gas processing

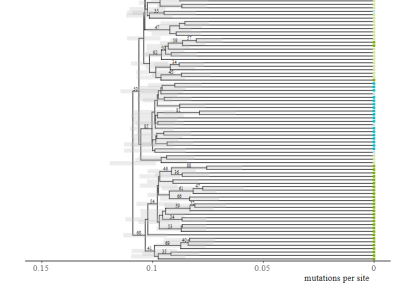

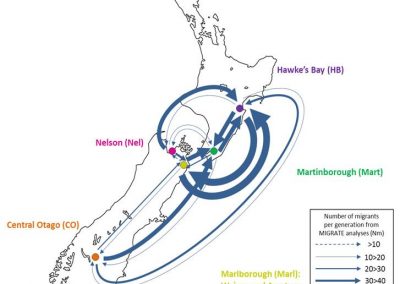

Molecular phylogenetics uses genetic data to reconstruct the evolutionary history of individuals, populations or species

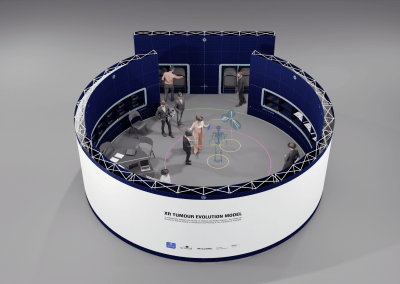

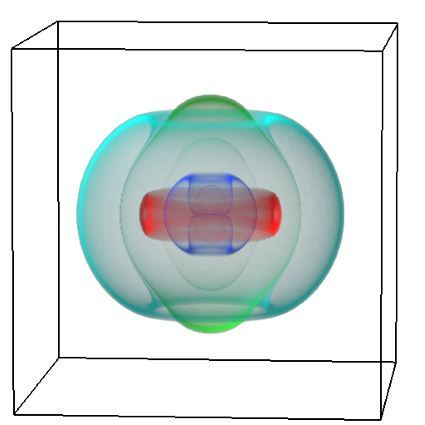

Wandering around the molecular landscape: embracing virtual reality as a research showcasing outreach and teaching tool